George was born in Canada, but moved to the United States as a child when his father took a job as a wood pattern maker with the Ford Motor Company in Cleveland, Ohio.

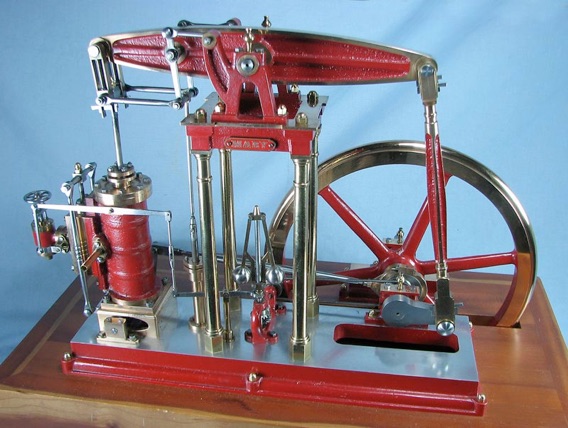

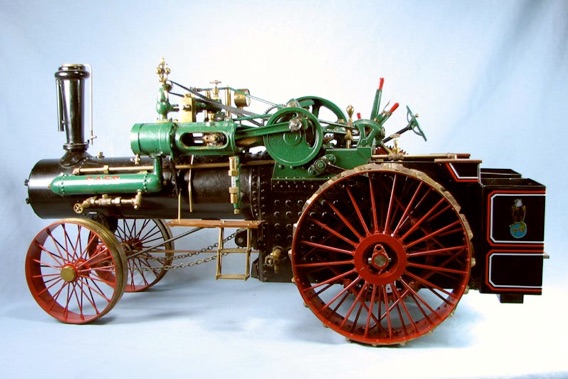

After being drafted into the Army during the Vietnam war he worked in a machine and maintenance shop. Several jobs followed after the army, lastly as an apprentice metal pattern maker where his father worked. That was the beginning of his career as an engineering craftsman, and acquiring the skills needed to get into the hobby of model engineering, starting with Stuart Turner kits, a Case traction engine and eventually I/C engines with kits offered by Paul Breisch.

His work at Ford meant that George had access to drawings for parts that were cast in the foundry where he worked. That enabled him to start work on a Ford 302 V8. Three years later it was finished.

At Ford he also learned AutoCAD and other CAD programs, plus CNC. CAD was used to design and make some of his own engines. Drawings for some of these, including an in-line OHV engine, are available from George.

However, George explains: “I consider myself an ‘old school’ craftsman. Do I use CAD to help visualize my ideas and designs? Absolutely! Do I use machines to remove and shape metal into the desired shapes, certainly! There’s no doubt that given enough time, a hammer, some sharp chisels and a file could produce things of beauty. Just look a the clocks, automatons and telescopes that were produced centuries ago, all with rudimentary tools.

“There’s no doubt that design and ultimately the process to produce a piece of art are not gifts given to everyone, but I guess I have to draw the line, although somewhat vague, as to how the part being produced is finished. Let’s take a couple of examples to clarify my position. At one time carved wood found in cabinetry and headboards was sculpted by hand. Today there’s not many who could or would want to pay for that type of work but with CNC routers a part that might take weeks to carve can now be done in days. Can the finished piece be considered ‘craftsmanship’, not really. Is it art, to be sure.

“Now, on to our interests, making miniatures, engines, guns and tools to name but a few. Could all the parts that comprise the indescribable work of Lou Chenot in making the model Deusenberg have been made by machines in this day and age there is no doubt. Could the finished product then be considered as to have been made by a craftsman, or a machine doing what it was told to do?

“I have seen countless examples of metal artistry through the years, with more and more of it being produced by CNC machines. There is nothing that can take away from the quality and exactness being produced by this process, but to me working metal, wood and glass by hand more befits the term ‘craftsman’.”