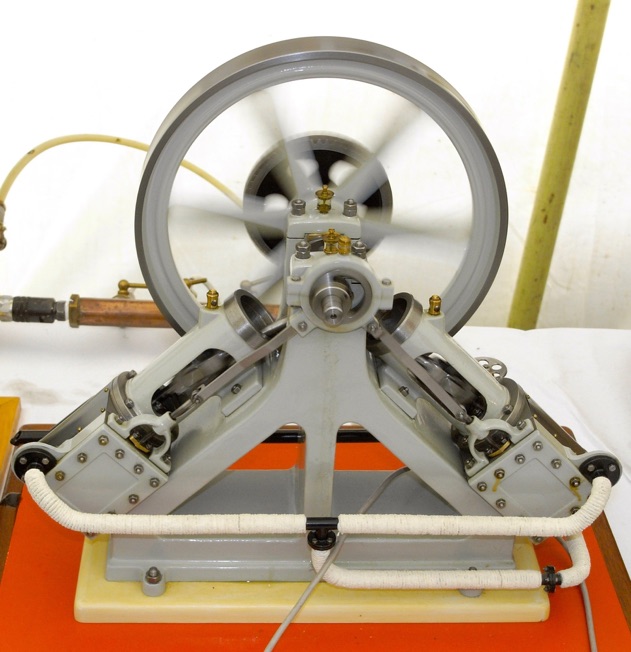

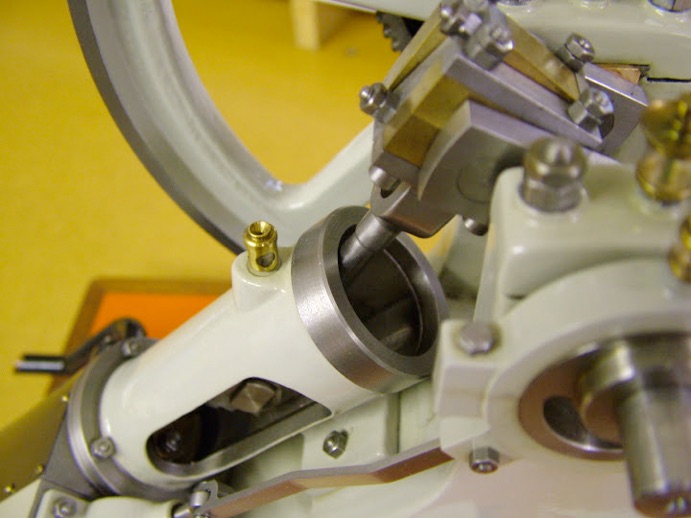

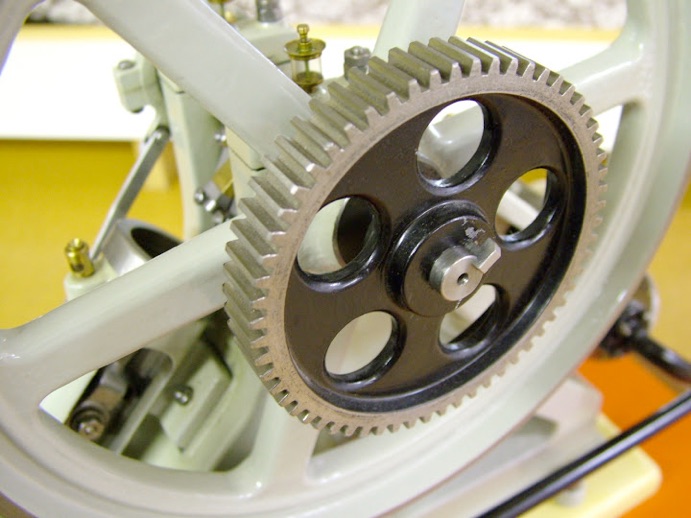

This model is of the Lang Bridge double-diagonal engine is typical of many engines used in the textile finishing trades to drive individual machines, much as an electric motor would be used today. Both the cylinders carry high-pressure steam and are 9" bore with slide valves and 12" stroke, the layout being such that it will start in any position. The cross-heads run in trunk guides, making a very robust design. There is no governor since it was normal practice to alter the engine speed to suit the machine's requirements by throttling the supply.

Many manufacturers built engines of this type but this example was made by the Lang Bridge Co Ltd of Accrington for the Bollington Printworks near Macclesfield. The date of manufacture is unknown.

It's a very near scale model of this engine in the Northern Mill Engine Society collection in the UK and was built from castings and drawings produced by Helix Engineering, a father and son team who had access to the original engine. The quality of the castings was truly superb and the drawings even better. In fact I would go so far as to say the drawings were just as good as drawings used on a daily basis at work.

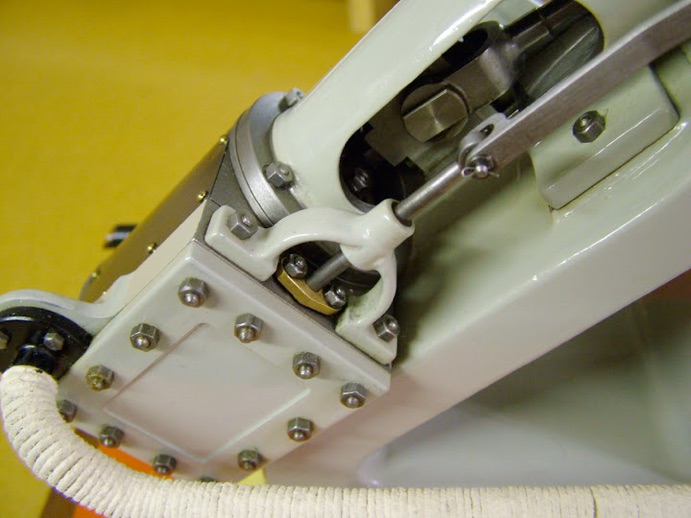

The main casting was a hefty lump and was held to a 'home made' angle plate (well works 'sponsored' - I had an extremely understanding and generous boss for such things) the only tricky bit being to ensure that the cylinder mounting areas were equally true to the centre line through the crankshaft.

I had no idea of the colour of the original but decided on using polyurathane paint used for a milling machine. It would be years later before I saw this ...