Back in the early 1940s K. N. Harris described an unusual horizontal engine which he modelled in 1:16 scale. He would go on to describe many more projects in his articles to Model Engineer magazine over the next several decades. He was often controversial, especially when critical of the designs of others, but he was always practical and to the point. It was fascinating to see this engine at the Brooklands show in 2016.

It is now in the SMEE collection and is one of the very many stationary engines in the keep of its members, which are now all in conserved condition.

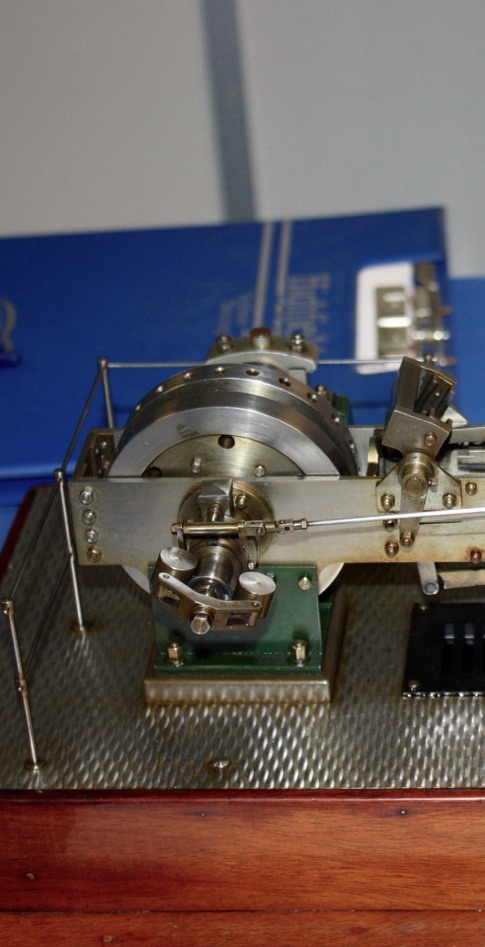

Looking for a project Harris remembered “an engine in the works in which I served my apprenticeship in the very early days of this century.” This engine was used to drive a small non-ferrous strip-rolling mill; it was horizontal and fitted with Allan link reversing motion.

Model cylinder is 5/8” bore by 1.25” stroke. It has a slide-valve on top, operated by Joy valve-gear .

The frames are of the plate type (made from gauge plate) with 4-bar crossheads and solid bushed main bearings. The flywheels are between the frames, mounted on the circular webs of the crankshaft. The connecting-rod big-end is of the marine type and is the only split bearing on the engine.

The governor is of the shaft type and operates a butterfly valve via a yoke and a shaft universally jointed at each end. General lubrication is taken care of by wick-feed lubricators for the big-end, main bearings, slide bars and valve-rod guide, while an oil-cup with screwed filler-plug is used on the little-end.

K. N. wrote: “That abomination of desolation (to the model engineer, and incidentally that is a title to which I am not ashamed to aspire) the slot-headed screw, is conspicuous by its entire absence; there is not one, seen or unseen, on the whole job (unless you count the wood stand!) Every stud, set-screw, bolt and nut I made, and there are some 320 of them all told, mostly B.A. threads. The only finished products that I used throughout the job were the round-headed rivets in the stands.”