Graham Meek’s

SCREW-CUTTING CLUTCH

DEVELOPMENTS

Graham Meek’s

SCREW-CUTTING CLUTCH

DEVELOPMENTS

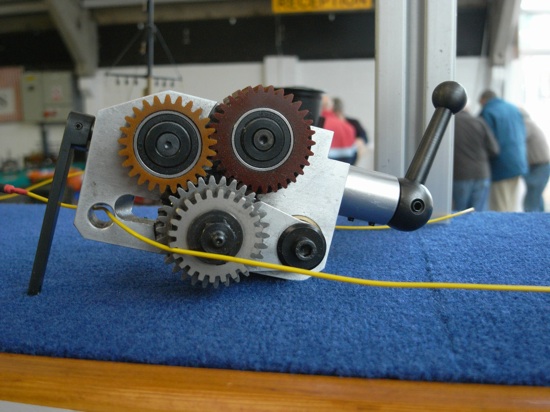

SOME time ago, Graham Meek designed and built a screw-cutting clutch for the Myford Super 7. This was updated and described in Engineering in Miniature magazine and later in Gray’s excellent book, Projects for Your Workshop, Vol 1, published by TEE, with some assistance from Ken Willson and others, including Phil Procter. Phil’s version is pictured here, and was a pre-publication prototype which included modifications including Tufnol gears for quiet running and to allow gear teeth to strip in a ‘crash’ situation.

“Normally,” explains Phil “if you need to cut a ‘non-imperial’ thread on a lathe with an imperial leadscrew you would have to stop the lathe and manually wind the spindle backwards at the end of each cut.

“With this unit you simply flick the ball handle over to reverse the leadscrew, then add another cut to the top slide and flick the lever the opposite way to make another cut. The cut is ended with the saddle trips the stop rod at the back of the lathe, and pops the clutch into its neutral position.

“Its so easy I now find myself looking for things to make with metric threads!”

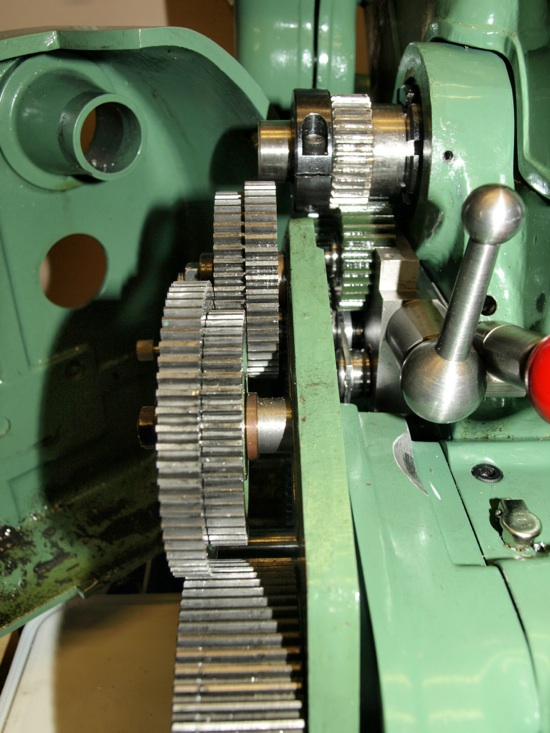

KEN WILLSON’S version of this clutch was on display at the Sandown Park Exhibition and takes things a step further.

Ken reports: ”Early in 2011 Gray decided to re-visit the design and not now having a Myford Super 7, worked with me, Ken Willson, and Tony Pratt to move forward with this new project. I was able to produce all the necessary dimensions of the Myford Headstock using a digital probe and readout system, working in 3 dimensions. What followed was a period of assessment and we then all set out to prove the drawings prior to the publication in the article and the book.

Ken adds that although designed for bronze gears, this version is using OILON Nylon 6 gearing as an experiment in noise control. He has bronze and TUFNOL gears available for later in the experiment.

“In use the unit has improved my screw cutting speeds as well as significantly reducing the time to complete as there is no necessity now to stop, reverse and run forward again when the half nuts are kept engaged for metric threading, the tool is merely withdrawn and the lead screw reversed ‘on the fly’. ”

Graham Meek’s version for a Warco BH600 lathe (also sold under other names) has now been drawn up by Graham Howe. We will publish those drawings next time.

Making and using Graham Howe’s own screw cutting clutch has been described in detail on these pages.

MODEL ENGINEERING

MODEL ENGINEERS

MODEL ENGINEERING WEEKLY WEB MAGAZINE

MODELS TO BUILD

GREAT MODELS

TOOLS FOR MODEL ENGINEERS

MODEL ENGINEERING FOR BEGINNERS

MEWS IS SPONSORED BY - HARROGATE EXHIBITION - TEE PUBLISHING - MERIDIENNE EXHIBITIONS - LYNX MODELS - CAMDEN MINIATURE STEAM - TRANSWAVE CONVERTERS - MESSE SINSHEIM - CHRONOS - PAULTHECAD.CO.UK - ECCENTRIC ENGINEERING