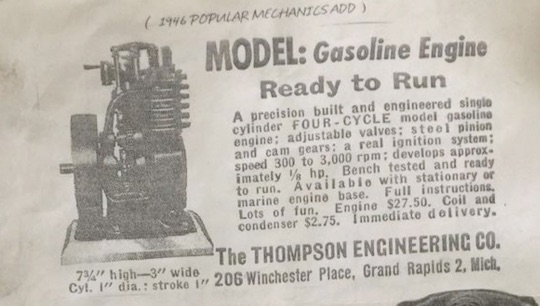

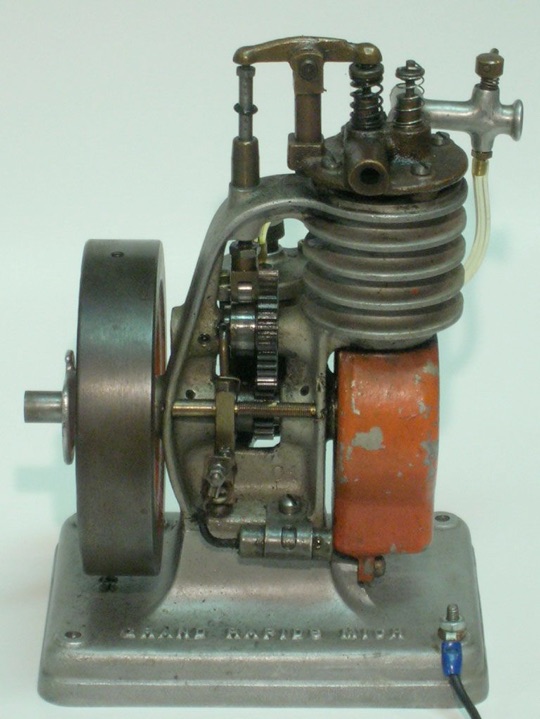

This engine was originally available from The Thompson Engineering Co of Grand Rapids, Michigan, in ready to run form.

A casting kit was later available from Sissons that had some differences to the original such as a more angular frame and different head layout.

Bob Herder's version seems closer to the original.

Rather than take the simple route of locating plans or even a set of castings where someone has done the work for you I opted to design my own from various images found on the net and basic sizes given in the advert. I went for my usual 24mm bore and full metric conversion with stock sizes and metric threads etc. As I'm unlikely to run this in a hull or chassis where some cooling is available I decided to include a cooling fan and also a means to adjust the timing while running, this is the result of a few evenings spent with Alibre showing the main components and general layout.

I made a start on the open frame as this is the main part of the engine and the one requiring the most work. To get a nice solid construction , and reduce the number of parts in the single fabrication, I used a section cut out of a PFC (parallel flange channel) structural steel to form the vertical leg that carries the boss for crankshaft, camshaft and the bottom of the cylinder. This also had slots milled in for stiffening webs and a couple of holes for screws to keep things together while soldering.

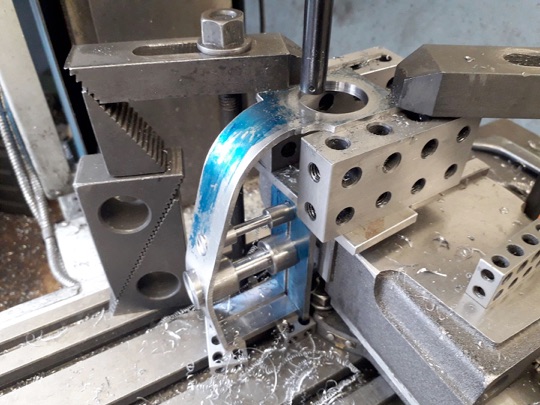

Next a slightly over-width strip was cut from some 3mm steel sheet and that was easily bent without the need to anneal or use heat to the required shape using a 1:1 drawing as a guide to check that the bends were correct. The bent strip was then clamped to the mill table and most of the excess width milled off down the sides to keep the mass as small as possible so things would heat up quicker when it came to soldering.

With the end that will go around the top of the head set vertical to the mill table, holes were bored for the various bosses.

Here you can see the hole being bored that will fit over a spigot on the top of the cylinder. You can also see the bottom plate and bosses in place, again these have had the excess material in the middle turned to a waist so there is less to heat. Note the use of 10-20-40 and 20-40-80 blocks rather than 1-2-3 as this is a metric build.

Part two here