USS MONITOR

ENGINE BUILD

by Vince Cutajar

USS MONITOR

ENGINE BUILD

by Vince Cutajar

The USS Monitor was an ‘ironclad’ steam ship which famously saw service in the Civil War in the early 1860s. The ship's engine was designed by John Ericsson as a "vibrating side-lever engine." He had created similar engines before and decided to use the design again because of its advantage for a small, low-riding warship.

Most steam engines of the time had vertical pistons, which occupied a lot of space and made them vulnerable to enemy fire because they were partially above the waterline. In contrast, the Monitor's 30-ton, 400 horsepower engine had pistons that moved horizontally, which reduced the height of the engine and allowed it to be mounted below the waterline.

Although a successful fighting ship the Monitor was not stable in rough seas due to its formidable rotating turret and sank in the early hours of January 1, 1863.

The engine was recovered from the Monitor's wreck site in 2001. It is now resting upside-down in an alkaline solution to inhibit corrosion. Over the coming years, conservators will continue to clean and separate the many different pieces of the engine to preserve them properly.

The first model Monitor was shown at Harrogate in 2014 by Brian Stephenson to the design of Bob Middleton. It was built without castings, like Bob’s other designs. Julius de Waal has produced these CAD drawings for both metric and imperial (see here) versions. Drawings can be downloaded for personal use only.

This one is built to Julius’ metric drawings.

I like to start a project with something simple which does not have to fit with something else. Item 4 was a good candidate for this. It is the outrigger top plate and two are required. I am using 6mm thick and 50mm wide flat bar for these. Started by getting the length to size.

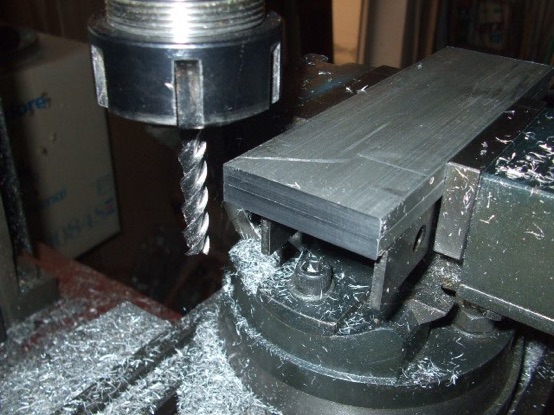

Next was item 3 which is the outrigger base frame. Two of these are required. These are 25 x 25mm and I actually found aluminium bar stock of this size, but by the time I would clean up the sides from all the dents and scratches, the finished size would be much smaller. Next size up that my supplier had was 30 x 30mm! So I had to spend some quality time with the mill bringing it down to size.

Part one here Part two Part three Part four Part five Part six Part seven Part eight Part nine Part 10 Part 11 Part 12 Part 13 Part 14 Part 15 Part 16 Part 17