IT WILL come as no surprise that one of the entries for this year’s Model Engineer Exhibition is Cherry Hill’s Blackburn traction engine of 1863 following on from winning a Gold Medal, her ninth, last year. It is now entered in the top competition for the Duke of Edinburgh award, which Cherry has won no less than eight times previously. Competition organizer, MIchael Law, is delighted that there are already entries at that level for the December event. He is also keen to encourage others to display their work. Cherry’s first model won a Bronze Medal, and that is within the grasp of many other model engineers. Cherry points out that she is self-taught, and hopes that other newcomers to model engineering will take encouragement from that and display their models.

This is the second model of a Blackburn engine that Cherry has built. Both result from extensive research. Indeed it is the research phase of her models which is critical, and few exhibition visitors can have any idea of the amount of work that goes into one of her models, even before a piece of metal is cut.

Usually research into a model is carried out while the previous project is being built in the workshop. Research is a combination of combing Patent Office records, The Engineer magazine and other contemporary publications such as the Mechanics Magazine. The research goes beyond just information about the machine itself. That is usually incomplete and so research extends to components from other contemporary designs. Also the background of those involved. In the case of the Blackburn agricultural engine of 1863 there are certainly no surviving examples to measure up - indeed there is no evidence that one was actually built.

Following the research comes the design phase. In the case of the Blackburn engines that included examining why the originals were not successful, but nontheless fascinating and original designs.

Both of the Blackburn designs were unique in that the boiler was located inside a large drum which acted as the driving wheel. The reader will quickly see that this arrangement presents a number of problems - getting coal and water into the boiler and the smoke out into the chimney are obvious ones. There are others.

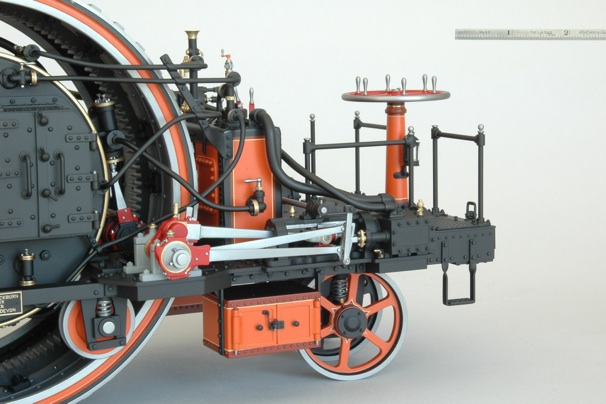

This second engine, with a horizontal boiler, overcomes many of the problems of the first one, but still represents a real challenge to the modeller. The boiler and crankshaft are placed inside the drum, with the cylinders fixed to the front of the frame each side of the three guiding wheels. The boiler is connected to the frame. Flanged wheels are also fitted to the frame and these run on rails fixed to the inside of the drum. The fire doors, ashpan doors, smoke box, chimney are at one end of the boiler.

Information on the Patent drawings is incomplete or unclear in many respects. Cherry had to use her own ingenuity on some major components including the boiler, crankshaft, valve chest and eccentrics, front suspension and steering. Parts not shown at all include the regulator, pump, injector, and water gauge. Choosing suitable designs and locations for all these was part of the research and design processes.

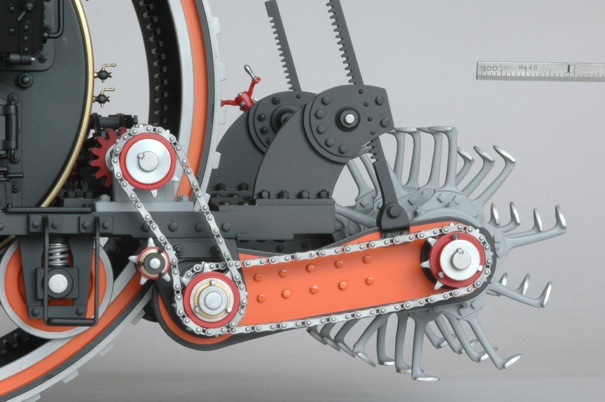

The engine is fitted with a digger/scarifier. A shaft is fitted inside the drum to the rear of the boiler for the drive. This shaft is driven by a dog clutch operated pinion engaging with the large internal gear on the inside drum surface. A standard ‘towing bracket’ fitted for general agricultural work is removed in order to fit the digger cylinder.

The model is built to Cherry’s usual scale of 1:16 or 3/4in to the foot. The drum is 6.86 inches over the bars equivalent to 9ft 2in in full size. Drum width is 3.75in equivalent to 5 feet. Model operating speed is 60 rpm - a scale equivalent of 2mph. At 180 rpm equivalent full size speed is 6.1 miles per hour.

No castings are used in this model, or any other model Cherry has built for the past forty years. Everything on the Blackburn is fabricated or machined from solid. Nothing is bought in. Cherry made the spur gears, internal gears, worm , worm wheel and racks. Also the transmission chains and sprockets, small retaining chains, name plates, chequer plates and all nuts, bolts and studs apart from a few fasteners used during fabrication, of which no trace remains to be seen. Every rivet is hand made.

The boiler is made of steel - just like full size. ‘Bare metal’ parts are given a finish to represent the type of iron that would have been used at the time.

The paintwork is sublime and took five months - a lot for a model that is only about a foot long.

Anything less than perfect is rejected and re-made, however minor and inconsequential the fault may be.

Even before the model proper was started, a mock-up was made to test the design. Many parts on the mock-up were completed to the standard of the finished model. However, no such parts are re-cycled on the final product, they are all made afresh.

In total the model took two years to research and make initial sketches and seven years to produce drawings and for the construction. The model contains around 7400 parts and occupied some 7500 hours of work over a nine year period. After all that the model will be given away, like all her other models, mostly donated to the Institution of Mechanical Engineers of which Cherry was made a Companion. She has twice won the Sir Henry Royce Trophy for the Pursuit of Excellence. In 2000 she was awarded an M.B.E. for Services to Model Engineering and became an Honorary Member of the Society of Model and Experimental Engineers in 2004. Her awards at the Model Engineer Exhibition are too many to mention in a short article. Cherry has been a supportive member of the SMEE for many years, and spends a good deal of time talking to exhibition visitors about her work and giving encouragement. The SMEE has provided invaluable support to the exhibition throughout its 100-odd year history and once again will contribute greatly with its lectures, demonstrations and displays in 2011.

So, does the model work? Yes! Cherry tests all her models when completed. Some are working that would never have worked in the original Victorian design. Her designs are often sufficiently detailed for a full-sized version to be built and which would work better than the original. The 1863 Blackburn ran successfully on compressed air around the workshop floor before being displayed.

PHOTOS BY CHERRY HILL

MEWS IS SPONSORED BY - HARROGATE EXHIBITION - TEE PUBLISHING - MERIDIENNE EXHIBITIONS - LYNX MODELS - CAMDEN MINIATURE STEAM - TRANSWAVE CONVERTERS - MESSE SINSHEIM - CHRONOS - GS SUPPLIES - PAULTHECAD.CO.UK - GLR DISTRIBUTORS