...continued

Next job was the gudgeon pins. They are silver steel again with bronze inserts in the ends to avoid scoring the bores. I pressed the bronze plugs in the ends and then turn the assemblies to length.

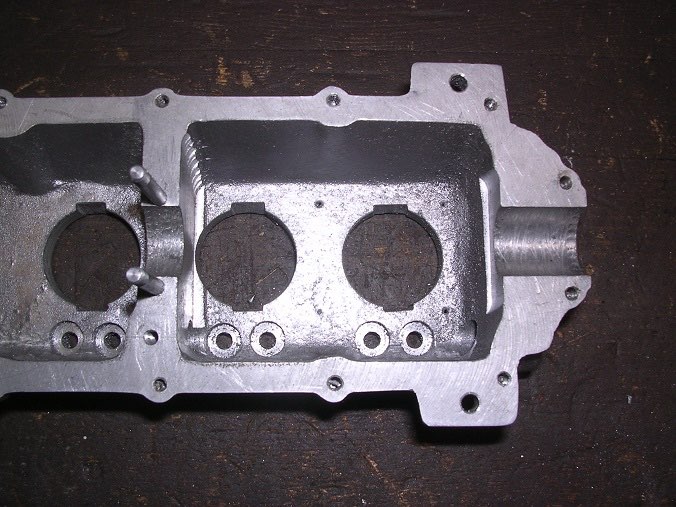

At this point, I found that on tdc, the block was lifted off the crank case! I checked the lengths of the bores and found them to be OK. Then I made a dummy piston on a piece of rod and tried it in the bores. It appears that the liners have all squeezed in a couple of thou at the top. To get over this, I thought I would just taper the top of the piston above the ring so, as a trial, I used some emery paper on the top 2mm of the dummy piston and it did the trick. I then went back and did the same to the working pistons and all was well. Another hurdle overcome!

So I could now get the pistons to the top of the bores. However, the crank would not turn past the 3 o'clock / 9 o'clock position. A look inside revealed that the sides of the rods were touching the crank case and the bottom edges of the bores. That took some careful work with a needle file to sort out.

I parted one off as a trial first to check the thickness and then use to sort out a process of breaking and then heat treating them.

I found that a cold chisel just gently tapped over a vee did the job nicely.

The heat treatment had been worrying me but I was told just to spring the ring out to the required size and place over a piece of steel before heating to bright red. You will see the ring relax after a few seconds at that temperature so then just let it air cool. Surprisingly, that worked a treat and I was very pleased with the outcome.

I parted off more rings until I had run out of bar and then treated them in the same way.

The crank now turns smoothly with four pistons and four rings fitted. A bit time consuming but very satisfying.

Part16 here.