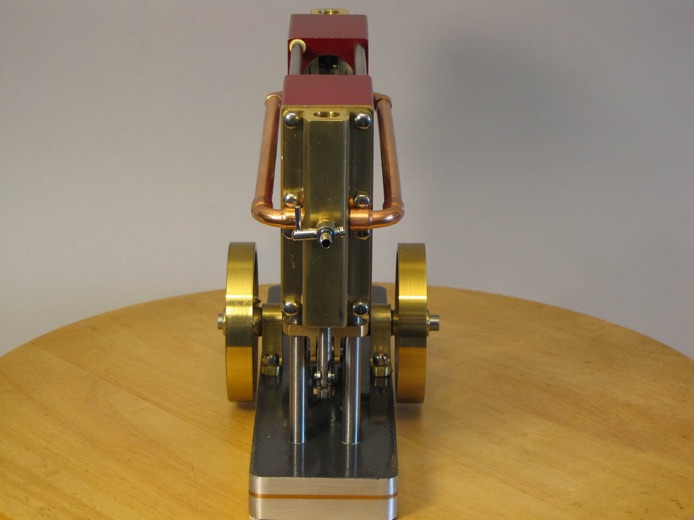

4-CYL ROCKING CROSSHEAD ENGINE

HaJo Franken

4-CYL ROCKING CROSSHEAD ENGINE

HaJo Franken

My latest model is the 4-Cylinder with Rocking Crosshead by Julius De Waal. Full drawings here.

The machine shows an interesting movement sequence and runs nice and quietly. But it is probably not very efficient and impractical because it has two dead centres despite having four cylinders. The reasons are that all four cylinders only act single-acting and two of them are at dead centre at the same time. There is only one connecting rod to the crankshaft via the Kreutz head.

Since only simple, usual turning and milling work occurs during construction, I did not create a construction report. However, I would like to introduce a small special feature.

The pistons are made of aluminum with an Iglidur J tread. Since only precision steel tubes with an inner diameter of 27mm were available, I changed the intended dimension for the cylinder from 30mm accordingly.

I used iglidur J plain bearings as the sliding and sealing surface

JSM-2427 i.e. Inside 24mm; outside 27mm; Length 30mm.

IGUS plain bearings always have a slight oversize. Only when pressed into the precisely fitting H7 bore do the bearings have the exact H7 tolerance dimension.

The aluminum piston holder is turned to 24mm, the sleeves are turned to a length of 28mm and slotted lengthwise at a slight angle of 1mm. When pushed onto the pistons, the slot in the cylinder closes and the pistons are tight and very smooth-running. Unfortunately, I have no experience with steam being ideal for air operation.

In a first attempt I used two 14mm sleeves. The idea was to achieve better sealing through the offset slots. - In a first attempt I used two 14mm sleeves. The idea was to achieve better sealing through the offset slots. But it was a sentence with an X, It was nothing, the short sleeves twisted open over the slanted slot and got stuck.