In about In about 1935 Stuarts introduced the ‘lightweight’ petrol engine, a 2-stroke spark ignition engine of 30cc capacity. This was available in both air and water cooled versions, it is the latter water cooled engine that is the subject of this build.

I had bid on a couple of part-made engines on ebay but they went for more than I thought they were worth. I also got to handle an untouched casting set but even that had a few flaws so I thought I may as well make one from scratch, at least you know where you stand with a block of solid metal. As you can see from the above to make the engine live up to its lightweight name Stuarts used Electron for some of the castings which was a magnesium alloy but I have opted to use 6082 for these parts. To make fabrication easier I also opted for steel for the cylinder with an inserted iron liner, here are the main bits of metal ready to make a start, with help from some old drawings.

I decided to get going on the cylinder so a bit of 2.625" steel that I have had for years was popped in the lathe and a lump parted off - I did hacksaw the last 10mm. On reflection I would rather have bought a known bit of steel as this was not the nicest to machine but as it is going to represent a casting the finish is not critical.

The outside was machined to profile - you can see the poor surface finish.

Next the hole for the liner was drilled and then bored out 1/16" undersize. You can't easily see it in this photo but a section of the hole was increased in dia to form the water space that surrounds the top of the liner.

The embryo cylinder was then parted off leaving an over-thickness flange at the bottom and a lump in the chuck which the head can be made from later, though I did just take a skim off the flange clean up the parting cut.

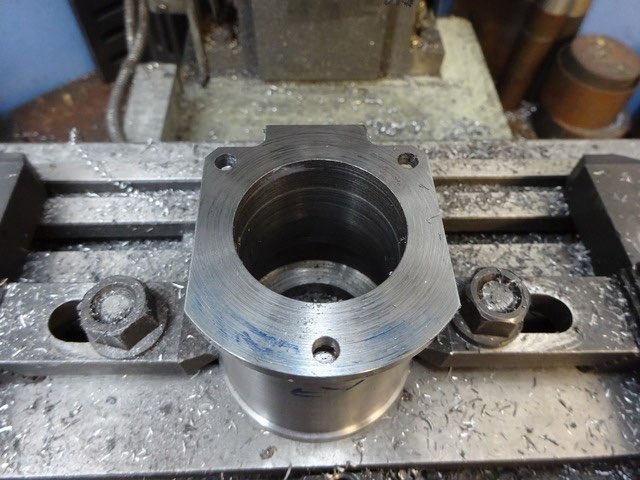

The flange was then drilled for the fixings and shaped to profile which gave me some straight edges that I could reference against for the next stage.

But before that an inlet boss was needed so with the vice on the rotary table that was milled out of a steel offcut

Closely followed by the lump that forms the transfer passage.

See Part one here part two part three part four part five part six part seven part eight part nine