ED: After this was first published we decided to re-do the drawings in an improved format. The replacement articles on the website have somehow become lost, so we are publishing again this popular project for a sundial that tells ‘clock’ time.

As we all know, clocks evolved from sundials. In fact, sundials were more reliable than early mechanical clocks and were used by some authorities to set clocks to time as late as the mid 1920s. So, for those of you who like clocks, but dislike cutting wheels and pinions, here is a sundial that indicates ‘clock time’.

In order to understand the design of this sundial it is important to distinguish the difference between ‘Greenwich Mean Time’ (GMT), which is the time shown on accurate clocks and watches in England, and ‘Local Apparent Time’ (LAT), which is the time shown by ‘ordinary’ sundials. The difference between these two time defining systems is significant: For example, in early November an ordinary sundial, located at Greenwich, would be about 16.5 minutes fast, and in mid February about 14 minutes slow, relative to a clock set to GMT. This difference varies in a quite a complex manner throughout the year. In addition, the difference between GMT and LAT also varies as the ordinary sundial is moved in any direction away from Greenwich. The reason for this is outside the scope of this article but for more information on this and many other aspects of sundials see refs 1 and 2.

In fact, it was the spread of railways across England, in the mid nineteenth century, which bought about the introduction of GMT. Incidentally, GMT has been replaced by ‘Coordinated Universal Time’ (UTC). GMT is based on astronomical observation and UTC on atomic clocks. GMT and UTC are virtually identical, the difference being no more than a second.

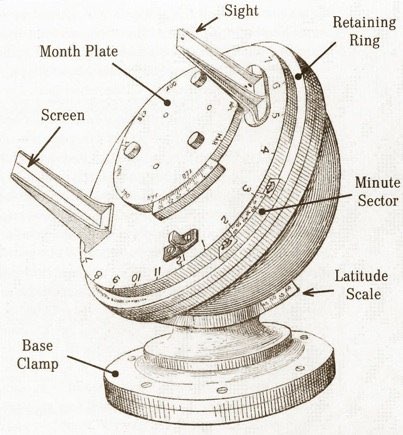

Before the introduction of the BBC time signal in 1924, some railways still set their clocks using a sundial. However, for the reason mentioned earlier, common sundials were somewhat difficult to use because they did not indicate GMT directly. The solution came with the invention of a special sundial called the Pilkington & Gibbs Heliochronometer (ref 3 and 4, fig 1). The P&G Heliochronometer indicated GMT directly and was reputed to be capable of being read to about one minute of GMT during the year (provided the sun was out!). Unlike ‘ordinary’ clocks and watches of the time, once it was set up properly, it was never slow or fast and, in fact, it was always as good as the earths motion about the sun which, as the basis of a time standard, was good enough in those days.

The P&G Heliochronometer was no doubt an accurate sundial. However, the price paid for accuracy was that, for ‘a quick look at the time’, it was not so easy to use as an ordinary sundial or a clock. One had to ensure that the month plate was set correctly and then, to read the time, physically rotate another dial so that the sun shone through the pinhole sight to project a spot of light centrally onto an engraved line on the screen (fig 1). Both the sight and screen are fixed to that dial and the time read from a scale fitted to the dial. I wanted to make a sundial which indicated UTC but which could be read more easily - rather like a clock.

EQUATORIAL SUNDIAL

My design is based on an equatorial sundial. The important features of this type of sundial are: 1) The gnomon (the axial rod which casts the shadow), is parallel to the earth’s rotational axis. 2) The hour dial is set at 90deg. to the gnomon. 3) The hour dial is divided into equal radial divisions, whereas, in an ordinary sundial the dial plate is horizontal and the divisions are unequally spaced.

The equatorial arrangement has a number of important advantages over the common sundial: 1) Does not have to be individually designed for a particular location relative to Greenwich. 2) Can easily be arranged to display UTC directly rather than LAT. 3) Can easily be adjusted to display either UTC or British Summer Time. 4) The hour dial looks rather like a 24hr clock dial – which was part of my design criteria.

(note: click on drawings to download/enlarge)

GENERAL DESCRIPTION

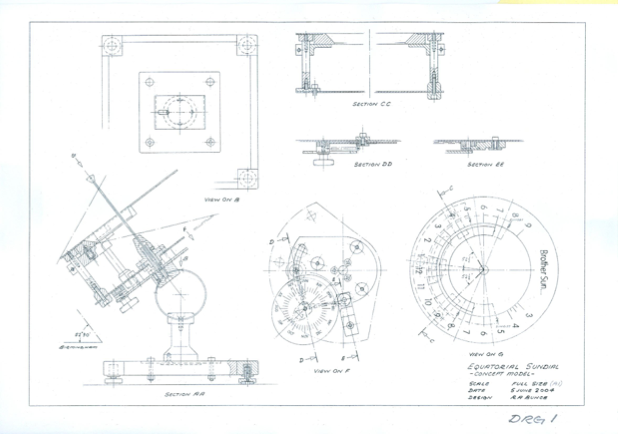

Figure 2 shows the general arrangement drawing of the sundial and photos 1 (above) and 2 (below), show front and rear views respectively. The hour dial measures 220mm diameter. This sundial was very much a concept model designed to explore new ideas.

The base is made of mahogany with beech lipping. There are four levelling feet with cork protective discs. The wooden base is merely for development purposes and is not weatherproof. Most of the other parts are made from brass.

The sundial mechanism is supported on a column via a short horizontal tube. The tube is fixed to the column and the sundial mechanism by large washers; each washer has a cylindrical face. The tube is provided with slots, rather than holes, so that the sundial mechanism can be set at a particular angle to the horizontal.

The mechanism assembly includes three main plates (fig 2, Section AA and View on F): The lower plate has a curved slot and is fixed to the tube via the special washers. The intermediate plate is sector-shaped and pivots about the central axis of the sundial. The intermediate plate has three bearing pads, which slide on the lower plate. Projecting from the intermediate plate are three columns, which support the third plate – the hour dial.

Screwed to the intermediate plate is the EoT cam (photo 3). This has a months dial glued to the upper side. A pointer fixed to the intermediate plate indicates the setting of the EoT cam. The EoT cam is spring loaded against a follower, which is pivotally mounted in the curved slot of the lower plate. Hence, by turning the EoT cam the intermediate and therefore the hour dial pivots about the axis. The position of the cam follower can be moved and locked along the slot - this also has the effect of turning the hour dial.

A second spring-loaded follower acts on the EoT cam at 90deg. to the first follower (photo 4). This is merely to provide a balancing action and avoids the need to physically lock the EoT cam after changing the month. However, the balancing action is not perfect due to the asymmetric shape of the cam and a shim-steel ‘curved’ friction washer is used under the EoT cam.

Located under the hour dial is an auxiliary dial. This is held in place by three ‘fingers’, each one being clamped to a column. The centre finger incorporates a spring-loaded plunger to bias the auxiliary dial against the bore of the hour dial and keep it in position. Hence, the auxiliary dial can be pivoted about the main axis of the sundial.

MATERIALS

Most of the parts are made from brass. This was purely for convenience at this stage of development. If ever I were to design and make the ‘new improved model’, I would use mainly stainless steel. Various pivots and the springs are already in stainless steel.

The three bearing pads, supporting the intermediate plate, are made from white polyacetal (Delrin), and the cam followers are PTFE.

The hour dial is brass on which is glued a paper dial made using CAD. The paper dial is covered with ‘sticky-backed’ plastic for protection. This is obviously not suitable of continuous outside use but is fine for development. If I were to make another dial, particularly one in stainless steel, I would consider using laser or water jet methods to cut and engrave the dial.

The auxiliary dial is made from plywood and painted gloss white – again, not suitable for outside use. In future, I would consider using opaque white Corian. This is an acrylic polymer filled with alumina trihydrate, made by DuPont.

The gnomon is made from NiTinol super elastic metal (ref 6). This is a nickel/titanium alloy discovered by the Naval Ordinance Laboratory, US, in 1962. NiTinol is difficult to machine – I could not cut it with a hacksaw and had to resort to grinding. The problem with the gnomon used in this type of sundial is that it is ‘free-standing’ and, if bent, will ruin the accuracy of the sundial. Figure 1, Section AA, shows that the maximum the gnomon can be deflected is about 90deg.; even this amount of deflection is within the elastic limit of NiTinol and, if bent, it springs back ‘good as new’. A remarkable material! ED: This material is now difficult to locate and most will find silver steel adequate.

ADJUSTMENTS

As indicated earlier, in order for any sundial to function properly it has to be adjusted according to its latitude and longitudinal location. This, together with other adjustments and features, are as follows:

Orientation: As with any equatorial sundial, the gnomon is aligned parallel to the earth’s rotational axis and the plane of the hour dial is parallel to the equatorial plane. So, in the upper hemisphere, the person reading the time would be facing south. An easy way to set the orientation is, assuming the hour dial and gnomon are mounted accurately on the base, use a compass to set the LH or RH side of the base to true north (not magnetic north).

Latitude adjustment: To make this adjustment, the two screws within the large supporting tube are slackened and the dial mechanism turned about the axis of the tube to set the plane of the hour dial relative to the horizontal (photo 2). This is only necessary when first installing the sundial or if it is moved to a different location. In Birmingham, UK, the latitude is about 52deg. 30min., the angle the gnomon makes with the horizontal is also 52deg. 30min (fig 2, Section AA). However, it is generally more convenient to measure the angle the hour dial makes with the horizontal; this is called the colatitude which equals 90deg. – latitude, so, in Birmingham, this is 37deg. 30 minutes.

Longitude adjustment: This is made by slackening the thumbscrew under the lower plate and rotating the dial assembly about the gnomon axis (photo 2). An easy way to set this is: first set the month dial to the correct date then, using an accurate clock, turn the dial so that the sun’s shadow indicates that time, then lock the thumbscrew.

UTC and British Summer Time: This is also done by slackening the thumbscrew under the lower plate and turning the hour dial forward or backwards an hour.

EoT correction: This is done simply by turning the month dial so that the correct month and week are adjacent the pointer (photo 5). The month dial incorporates the EoT cam, which turns the hour dial, via the sector-shaped plate, and so effectively converts LAT to UTC. Several people have asked me how to design and make an EoT cam so that is given in the appendix.

Summer and winter months: Like many other equatorial sundials, in the summer the sun shines on top of the hour dial and in winter below the dial (according to the dates of the spring and autumn equinoxes, which, for 2009, are March 20 and September 22). For ease of reading during the winter, I wanted the shadow cast by the gnomon to be visible from above. To allow this, the main dial is provided with the auxiliary dial with a non-graduated inclined surface (painted white).

Photo 6 was taken at the end of the first week in February 2009 and the month dial is set accordingly. The sun is shining on the underside of the dial and so the shadow is cast on the auxiliary dial and not on the upper surface of the hour dial. The time shown is about 11.35.

During the winter months, the difference between the earliest sunrise and latest sunset in Birmingham (and other places) is greater than 12 hours. This means that the auxiliary dial would need to encompass a span of greater than 180 degrees. However, this would mean that on some days, in the early morning or late evening, one end or other of the auxiliary dial would obscure the suns rays from casting a shadow on the opposite side of the dial. To avoid this problem, the auxiliary dial can be turned axially relative to the hour dial (photos 7 and 8). This allows the time to be read during all winter sunshine hours.

Accuracy: The dial is graduated in hours and quarters and can be read (estimated) to within about 2 minutes of UTC. This may be unimpressive by modern standards but, on the other hand, it never gains, never looses, doesn’t go wrong and doesn’t need batteries!

MOTTO

All sundials should have a motto! The motto on my dial reads: Brother Sun… from: Saint Francis of Assisi, Canticle of the Sun, c1225: “Be praised, my Lord, with all Thy creatures, above all Brother Sun who gives the day and lightens us therewith.”

REFERENCES

1. A.E. Waugh: Sundials, their theory and construction, Dover, New York, (1973)

2. The British Sundial Society: www.sundialsoc.org.uk

3. G.J. Gibbs: ‘Improvements in Apparatus for Indicating Mean Solar time’, UK Patent Application 10,787, 8th May 1906.

4. G.Aldred: A Review Of The Heliochronometers By Pilkington & Gibbs, Bull BSS, British Sundial Society Bulletin, 18(ii,iii), 90-131 (2006).

5. Intellectual Property Office: esp@cenet, Worldwide patent data base: http://gb.espacenet.com/search97cgi/s97_cgi.exe?Action=FormGen&Template=gb/en/advanced.hts