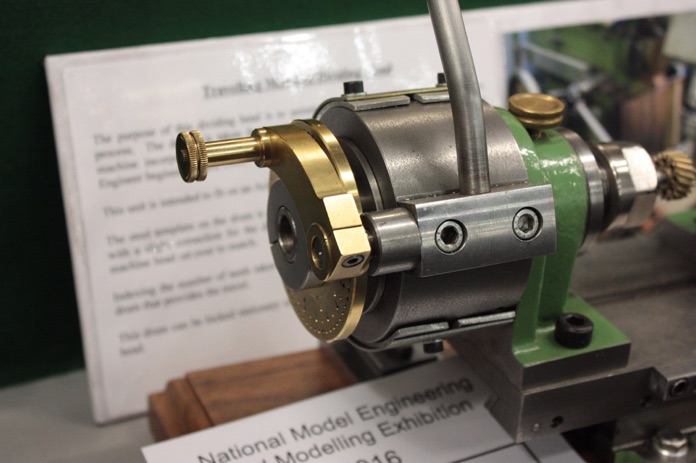

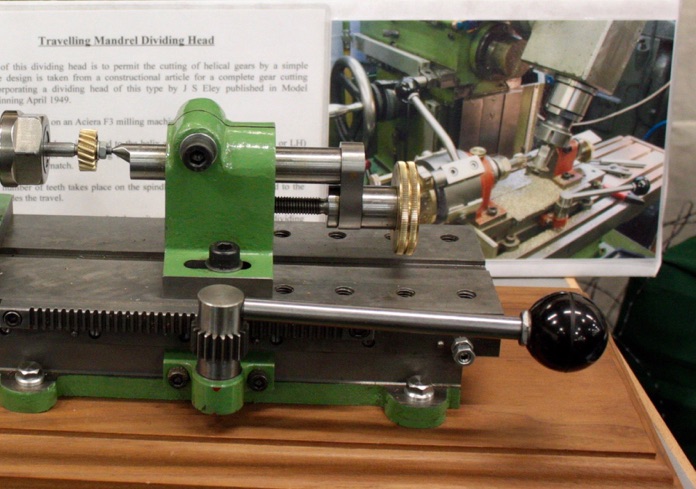

At the 2016 Doncaster exhibition, Mike Sayers showed, in addition to his Blower Bentley engine, a traveling mandrel dividing head used to make the helical gears. Inspiration for came from an article in Model Engineer in 1949 by J.S. Eley who wrote about the problem of making spiral gears for timing.

“I had no means at all in my workshop of producing gears of any type, and at first proposed to make an attachment for the lathe to cut the spur gears, and follow Mr Westbury's method of producing the spiral gears. Both methods were not without snags, however, and it was at this point that I interested Mr George Fisher, of Leeds, in the problem of generating spiral gears. To cut a long story short he got out a design for the machine which forms subject of this article.

“Although measuring only 12 in. x 8 in. x 12 in. it will produce spur, spiral, double helical, and bevel gears, up to a diameter of 4 in. The smallest gears so far cut are 3/16 in. diameter. In general design the tool resembles a small milling machine but with several notable differences. In first place, no cross traverse is provided, as in present case it is really unnecessary. Instead collars of varying widths are used to centre the gear cutter on the centre line of the machine table. Secondly, the cutter spindle is carried in an arm which swings about the vertical centre line of the machine. This is for setting the cutter over to an angle corresponding with the spiral angle of the gear to be cut, and is contrary to usual practice, where the table itself is made to swing.

“The third unusual item is the dividing head. In addition to the worm-driven movement for dividing, the whole unit is made to revolve round on its own axis.”

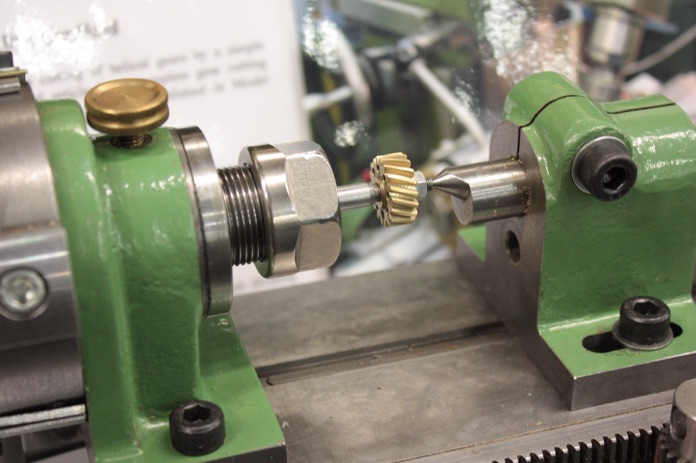

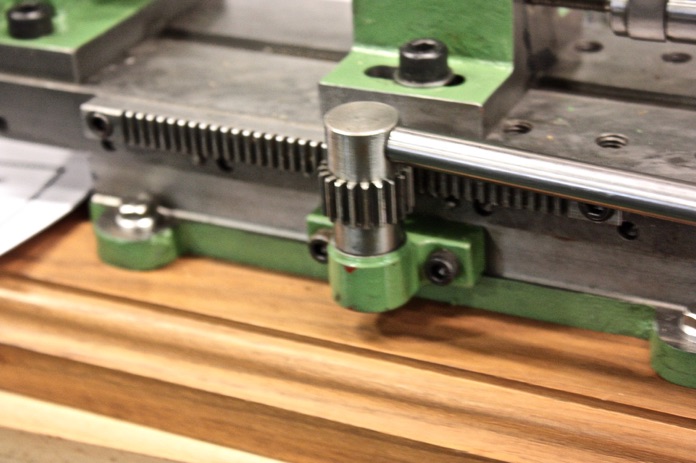

Mike adapted the dividing head element for use on his Aciera F3 milling machine. The steel template on the drum is shaped to the helix angle of the gear (either RH or LH) with a slight correction for the differing diameters of the drum and gear and the milling machine head set over to match. Indexing the number of teeth takes place on the spindle as normal as this is linked to the drum that provides the travel. The drum can be locked and the unit used as a simple dividing head.