JAMES COOMBES ENGINE REVISITED

Part one by Jason Ballamy

JAMES COOMBES ENGINE REVISITED

Part one by Jason Ballamy

Having enjoyed the "reinvented" Stuart Real project I thought that their James Coombes could do with a similar treatment to bring him into the 21st century. So I set to with a copy of Andrew Smith's book which is the cheapest way to get a set of the drawings and redrew it in Alibre to use mostly barstock and to metric standards. Some of the main points I wanted to address were:

•Do away with the cast box bed and outrigger bearing support and mount the engine on a "stone" plinth

•The sole plate and table on the stuart are just bits of flat 3/16" plate so these to be made to look a lot more like castings and generally more appealing to the eye.

•Similar with the plain columns to be replaced by ones with classic bases and capitals

•Do away with the soldered conrod which may put people off and not easy to solder it up true

•Do away with the clumsy bolt together eccentric rod and replace with a single straight piece

•Add decorative bands to the cylinder as I was not going to timber clad this one and do something with the inlet as I don't like that going in via the valve chest cover. And while I'm at it get rid of the chunky exhaust flange.

•Generally add a bit more detail but not go as far as things like fluted columns, wedged and cottered straps etc otherwise I may as well just build a Waller Table Engine.

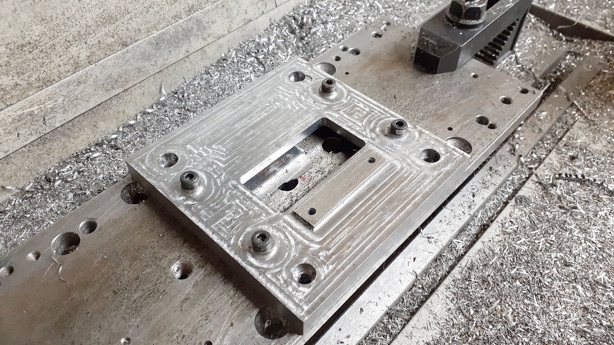

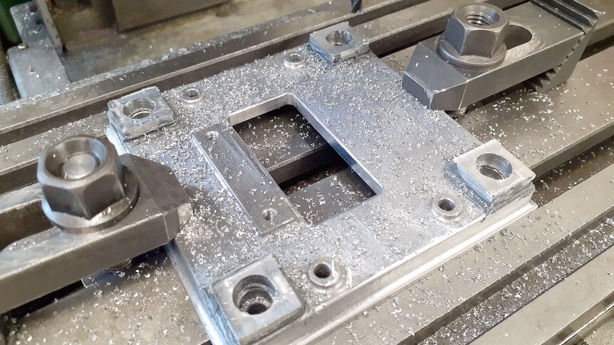

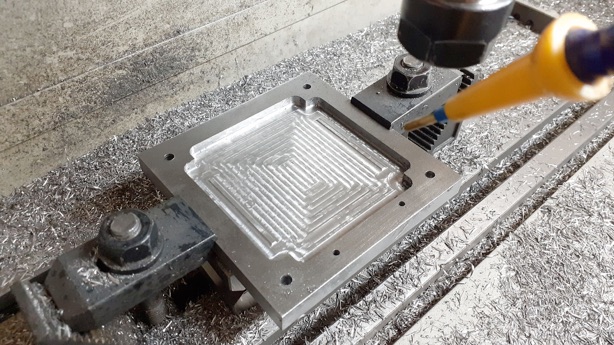

Starting with the sole plate and outrigger bearing base two pieces of 12mm plate were squared up on the manual mill to overall size. Then the soleplate was clamped to the CNC's bed with some packing below so that the four hole sthat will hold it to the base could be drilled and I also thinned down an area where the crankshaft clearance slot will be cut so that you don't see a thick edge around this hole as it would not have been cast full thickness.f

I find mounting the clamp bars the wrong way round is a good way to lower their profile so you can get in closer without too much tool sticking out of the collet holder.

Next four squares of steel were JB Welded into place and once set were milled down to an even 5mm high. These will form the bases of the columns.

It is also a good way to ease your way into designing completely from scratch as methods learnt modifying existing designs can be put to use when and if a modeller wants to move on to a subject that was never made available or has long gone out of production. Also lets not forget that without those that went down this route in the past we would not have the designs being built today, I'm sure some peoples casting stashes would be a lot smaller if the likes of Clarkson, Mount, Westbury etc had not designed engines from scratch and then shared their work with others.