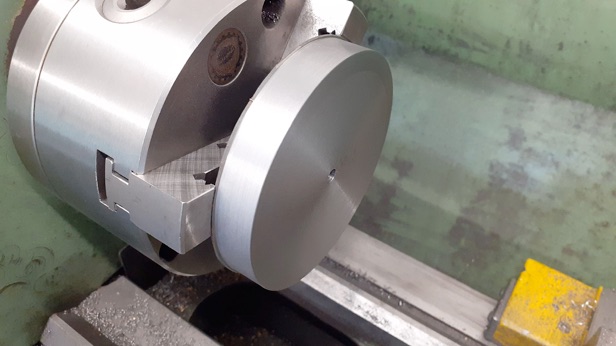

The engraving shows a flywheel with a fairly deep section rim which no doubt helps get the single acting piston back up to TDC, most castings of the right size seemed a bit lacking in mass so I drew one up and set about making it from a slice of cast iron bar that I had to hand which required holding by the minimal amount while some gentle cuts were taken to clean it up.

Once that was done I could get a decent grip of it to turn the other side and also cut a 1mm deep recess with a round nosed tool on each side to reduce the amount of milling required. The hub on the other side protrudes further to give room for the grub screw.

An adaptive path with a 6mm cutter followed by a ramp with a 4mm ball nosed cutter took care of the roughing and finishing firstly to just beyond half depth.

After flipping the stock over a shallower repeat of the above took care of the rest after which a quick tickle with a Dremel cleaned up any slight machining marks and gave a little texture.

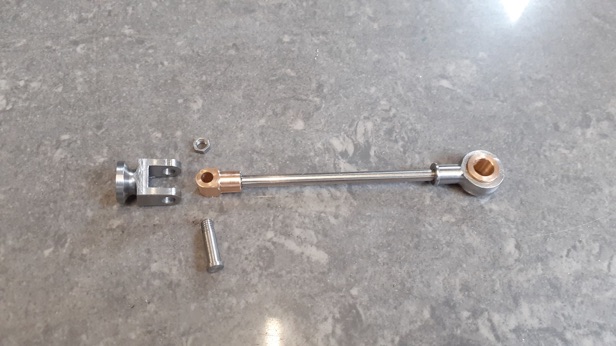

I did not take many pics of the con rod, just this one that shows the beginnings of the yoke that screws into the underside of the piston crown having the waist cut with cranked round nosed tool.

And one of the little end being turned and tapped after having been milled square and a reamed 3mm hole formed.

But I did take a photo of all the parts before putting them together, I just used Loctite to fit the big & little ends to the rod.

PART ONE HERE PART TWO PART THREE PART FOUR