The cylinder heads were next and the curvature was done as a series of flats using the top slide. The angles were roughly obtained by drawing lines on the drawing at a tangent to the head and measuring with a protractor. The major OD was turned to plus 0.1mm and each end taken to the minor diameter plus 0.1mm for approximately .5 mm inwards to serve as a guide. Once the flats were established the remainder was profiled using a scraper to end up as so:

A few minutes with a file and emery and 400/800 wet and dry saw them ready for cutting the fins.

A thinned parting tool which just happened to be near enough the right thickness worked fine and the fins turned without mishap.

Next were the spinners. After drilling and tapping, the insides of these were turned more or less by eye to a fixed depth using a ground freehand round nosed tool about 2mm wide. An accurately dimensioned register was then turned in for about 1.5mm depth. As these parts are cosmetic only no real attempt was made to make these as light as possible, just a reasonable attempt at weight reduction. The tommy bar holes were drilled before rough turning and parting off to do the outer profile.

A small stub of ali was quickly converted into a mandrel - the register turned to fit inside that on the spinner, the spinner pulled up tight on the (loose) 6mm stud similar to machining pistons.

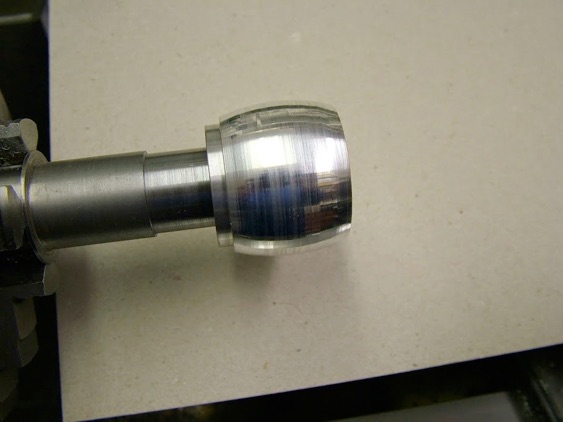

This gives a good accurate location - this is the rough turned blank with no 'by eye' perceptible run out.

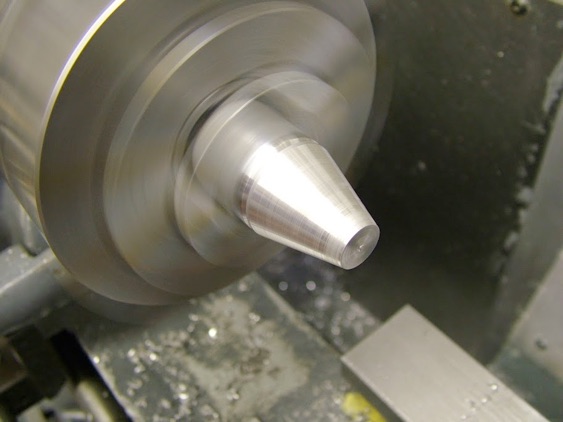

Again the shape was evolved using the same technique as on the heads: a series of flats.....

Followed by a 'scrape' ...

With the ali parts finished the bearing sleeves were made from cast Phos Bronze. Drilled bored and reamed 8mm the ODs were turned to a good (Loctite) fit in the front housings. Despite this process one of them suffered considerable run out so they were both set in a collet and bored out to 8.5mm. Improvement was considerable so this became the route taken for all future bearing sleeves.

With the prop driver collets made from brass and the small fuel jets from brass 4BA threaded rod this was the current state.

part one part two part three part four part five part six part seven part eight

part nine part ten part eleven part twelve