BUCYRUS ERIE 50-B

STEAM SHOVEL

Part six - making tracks - by Alberto Celot

BUCYRUS ERIE 50-B

STEAM SHOVEL

Part six - making tracks - by Alberto Celot

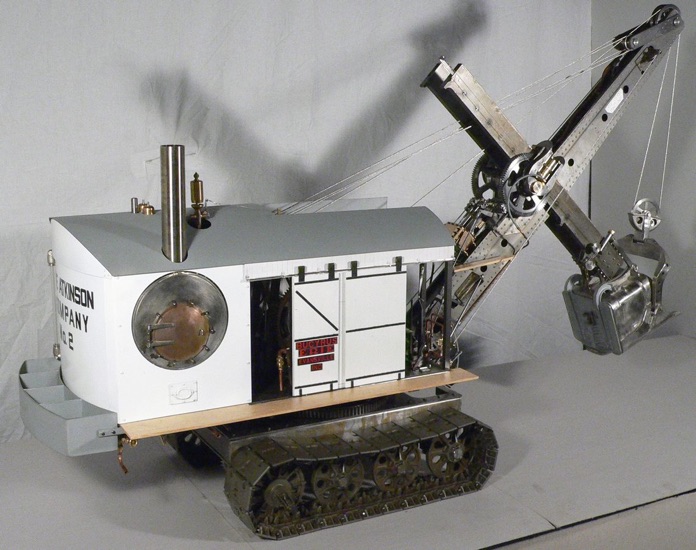

The work continued with the construction of the lower part (Truck Frame) equipped with the crawler tracks. The tracks are very complex, as are the traction wheels. After examining the various possibilities for their manufacture, such as casting or rapid prototyping, I opted for milling from solid, which ensures maximum strength and quality.

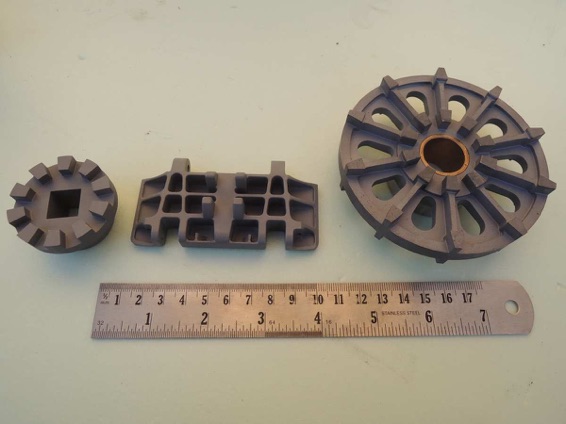

I used a company to make the wheels and other pieces, all made in C40 steel by milling from solid; the grey colour is due to blasting.

Let's start with the tracks: there are 56 pieces, 28 on each side:

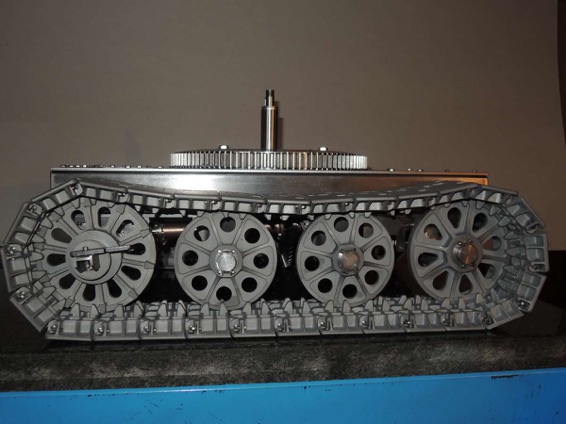

The tracks are driven by the driving wheels via two hubs which are inserted manually. The photo shows the drive wheel and hub with a track piece:

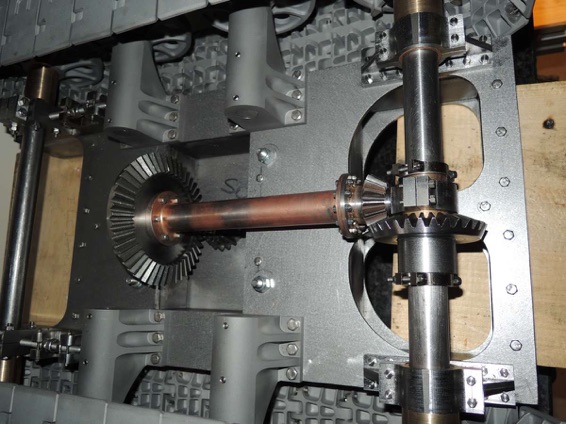

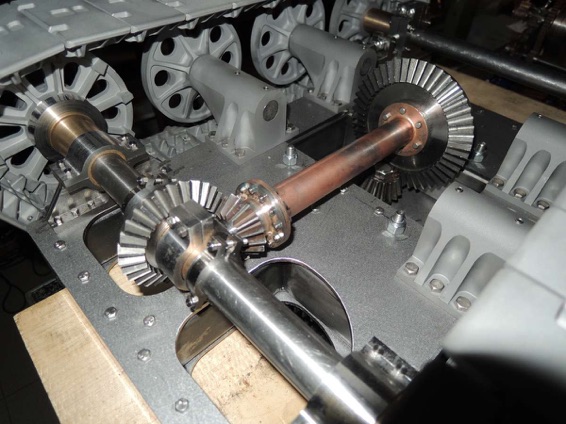

The two pictures that follow show the toothed coupling which couples the drive wheel to the motor shaft. In the first image the joint is in the disengaged position, while in the second it is in the engaged position.

The manual lever that is seen serves both to help the coupling, and to lock the coupling once engaged.

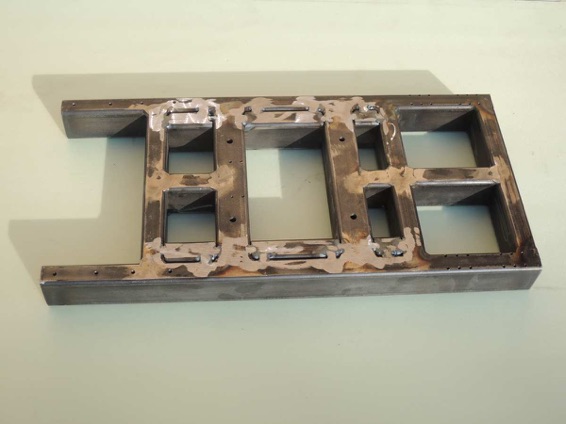

The four photos below show the underside, the gear transmission and the stretcher’s axis which can slide on the guide rails and be locked in the correct position to ensure the correct tension on the tracks.

Part one part two part three part four part five part six part seven Part eight

part nine part ten part eleven part twelve Conclusion

MEWS IS SPONSORED BY - CHRONOS - PAULTHECAD.CO.UK - ECCENTRIC ENGINEERING - WARCO - BRISTOL EXHIBITION - HARROGATE EXHIBITION - MERIDIENNE EXHIBITIONS - CAMDEN MINIATURE STEAM - TRANSWAVE CONVERTERS - CHERRY’S MODEL ENGINES -

Editor - David Carpenter