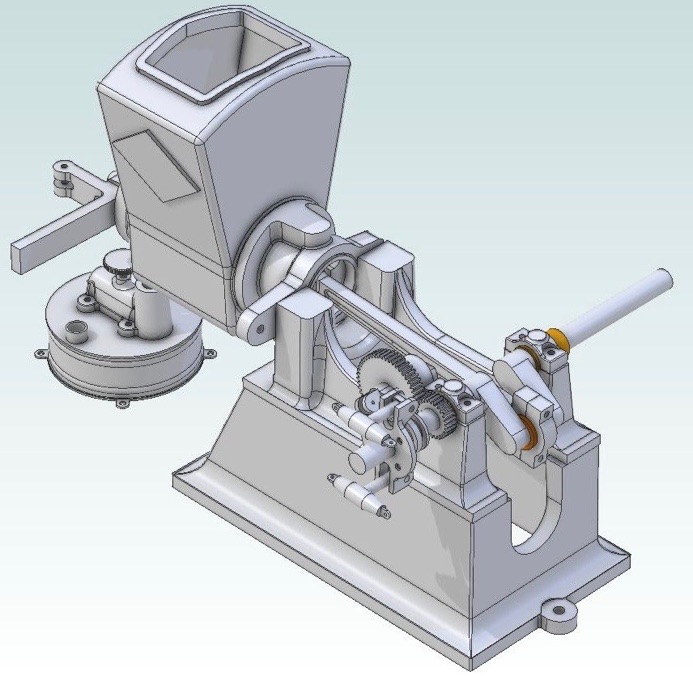

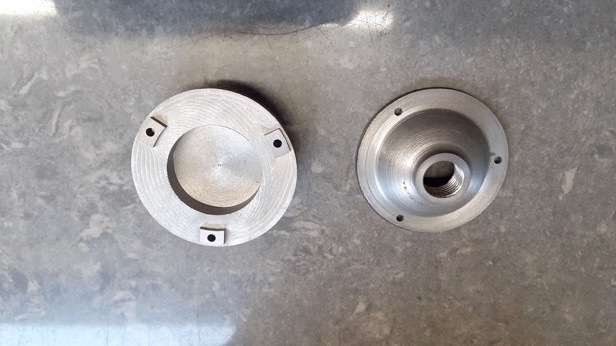

While up at the head end of the engine I thought I would get the last couple of small castings out the way. Starting with the silencer (muffler) halves, these were held in soft jaws to turn the overall diameter, and the cast surface was cleaned up a bit at the same time.

The halves could now be held the other way around and the flange machined to thickness, a cavity turned with a boring bar and in the case of the half that screws to the exhaust pipe that was drilled and tapped 1/8" BSP.

Most builders will probably opt to turn three spacers to fit between the halves but I left the flange on one half thicker so I could mill most of the material away and just leave three integral spacers.

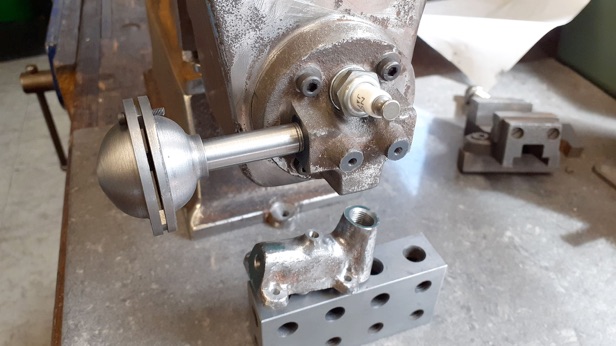

The other casting that can be dealt with now is the Mk2 carb. I started by holding it in the 4-jaw and got the needle boss to run as true as possible then faced the bottom and the stub that can be drilled part way and tapped M8 x 1 before continuing the hole right through and tapping M4 x 0.5 for the needle.

Holding by the spigot in a square collet block I could index the casting about to drill the long inlet hole and also drill and tap for the pipe that joins carb to head.

The last thing to do was spot face the four mounting holes with am 8mm milling cutter and then drill through 3mm for the screws that will hold the carb to the fuel tank top. Make a note of where the hole positions end up so they can be used when tapping the tank.

A quick group shot of the exhaust parts and carb.

PART ONE TWO THREE FOUR FIVE SIX