CAMERON STEAM PUMP BUILD

Part 14 by Jason Ballamy

Flywheel and piston

CAMERON STEAM PUMP BUILD

Part 14 by Jason Ballamy

Flywheel and piston

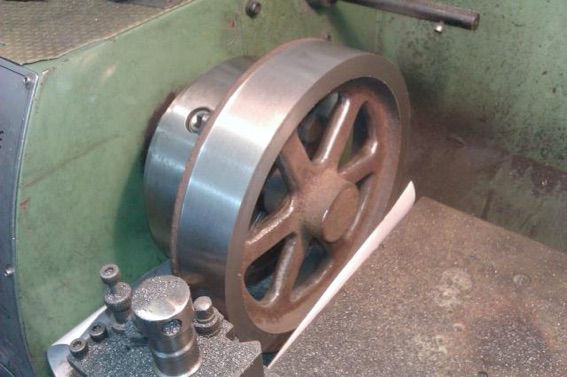

I used one of the 8" flywheels available from RDG as they are very reasonably priced. The surface can be a bit iffy but as I was going to paint the rim that was nothing a bit of filler could not sort out. I held it in the 4-jaw and got the inner surface of the rim running as true as possible. As there were a couple of inclusions in the surface I opted for my insert hold that uses the other two corners of the CCMT type inserts as they are a bit more robust and I have lots of unused corners, this needs to cut from the inside out.

Many full size steam engines have hollow cast iron pistons but in our smaller sizes its often easier to make a solid one so to compensate for the increased mass. I like to make my pistons from aluminium. A suitable piece was turned down until 0.010" overside and drilled & tapped for the piston rod. I then cut two grooves for the rings allowing for the oversize piston before parting off.

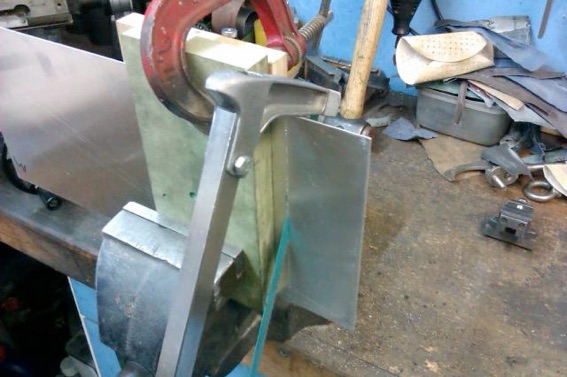

A suitable sheet of 0.8mm ali was held between two bits of MDF to support it and a strip cut off, by tilting the saw I could cut the full depth of the sheet.

GO TO PART ONE PART TWO PART THREE PART FOUR PART FIVE SIX SEVEN EIGHT NINE TEN ELEVEN TWELVE THIRTEEN FOURTEEN FIFTEEN