Continuing with things at the head end, the valves were done in my usual way by putting a small centre drill hole into some 303 stainless bar so that the stock could be supported with the revolving centre, and using a DCGT insert which can get in nice and close.

A 2mm dia insert was used to form a fillet where the stem meets the head and also to cut the 45deg seat.

While the valves were still part of the bar stock I used that as a handle to give them a quick lap with some 600grit silicon carbide powder and oil.

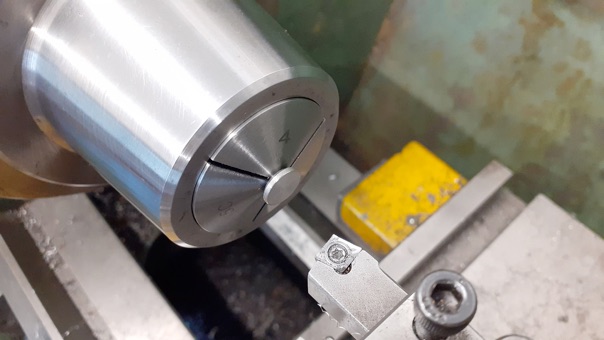

They were then sawn off and held in a collet to face the head, and then fitted from the back of the collet so that the centre drill hole on the stem could be turned away.

The rocker arm was cut to my new shape to allow for the inlet valve to be closest to the push rod, the curve allowing it to reach over that to the exhaust.

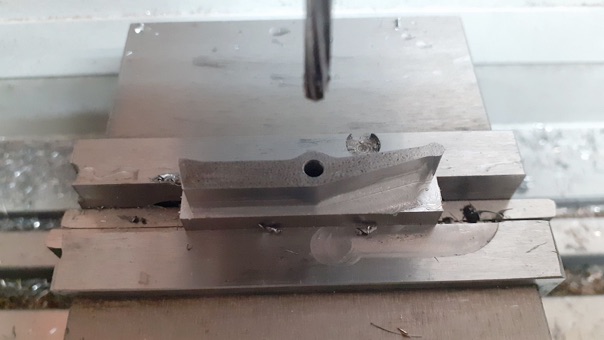

While I had the CNC going I also did the governor latch arm and the cam follower which also had two holes tapped for the latch.

All three parts went back into the manual mill to have the excess holding material milled away.

The cam follower was drilled to take a spigot that will be formed on the end of the push rod.

The latch arm was thinned down either side for looks more than anything.

Lastly the undercut of the latch was machined using a flycutter with a suitably ground HSS bit.

The reduced thickness could then be slotted and CSK for screws with enough length to the slot so its position can be adjusted.

PART ONE TWO THREE FOUR FIVE SIX SEVEN EIGHT NINE 10